As a Process Engineer at Tesla Inc., you immerse yourself in the dynamic world of one of the most innovative companies in the automotive industry. Working at the forefront of sustainable energy and cutting-edge technology, your role is crucial in optimizing and streamlining manufacturing processes to ensure the highest quality and efficiency. From designing and implementing process improvements to collaborating with cross-functional teams, you play a pivotal part in shaping the future of electric vehicles. With unmatched opportunities for growth and impact, a career as a Process Engineer at Tesla Inc. is both exhilarating and rewarding.

Responsibilities and Roles

As a Process Engineer at Tesla Inc., your main responsibility is designing and optimizing manufacturing processes. You will be tasked with identifying areas for improvement and implementing strategies to increase production efficiency and quality. This involves analyzing production data, conducting process simulations, and collaborating with cross-functional teams to develop efficient processes. In addition, you will be responsible for managing projects, including budgeting and ensuring timely completion.

Education and Experience

To excel in this role, a Bachelor’s degree in engineering or a related field is required. Previous experience in process engineering is highly desirable, as it provides the necessary knowledge and skills to effectively address the challenges of the position. It is important to have a deep understanding of manufacturing processes and systems, as well as familiarity with industry regulations and standards.

Skills and Qualifications

The skills and qualifications required for a Process Engineer at Tesla Inc. include strong analytical and problem-solving abilities. You will need to be capable of analyzing data and using it to drive improvements in the manufacturing processes. Excellent communication and teamwork skills are essential, as you will be collaborating with various teams within the organization. Proficiency in computer-aided design (CAD) software is also necessary, as well as knowledge of statistical analysis tools. Attention to detail and the ability to work under pressure are also crucial skills to possess in this role.

Daily Tasks

On a daily basis, you will be conducting process simulations and optimizations to identify areas for improvement. This involves analyzing production data, identifying bottlenecks, and implementing strategies to increase efficiency and quality. You will also collaborate with production and quality teams to ensure that the manufacturing processes meet the required standards. Monitoring and troubleshooting manufacturing processes are also part of your daily tasks, as well as implementing new technologies and automation to improve productivity.

Collaboration with other Engineers

Collaboration with other engineers is an essential part of being a Process Engineer at Tesla Inc. You will work closely with design engineers to develop efficient processes that align with the product requirements. By collaborating with industrial engineers, you will be able to optimize the workflow and implement strategies for effective resource allocation. Additionally, you will coordinate with quality engineers to ensure that the product standards are met and partner with maintenance engineers for equipment upkeep and maintenance.

Problem-solving and Troubleshooting

Problem-solving and troubleshooting skills are vital in this role. As a Process Engineer, you will need to identify process bottlenecks and develop innovative solutions to address them. Analyzing data to diagnose and resolve production issues is an important aspect of your responsibilities. You will be required to implement corrective actions to improve quality and efficiency, as well as conduct root cause analysis for process failures and implement preventive measures to avoid similar issues in the future.

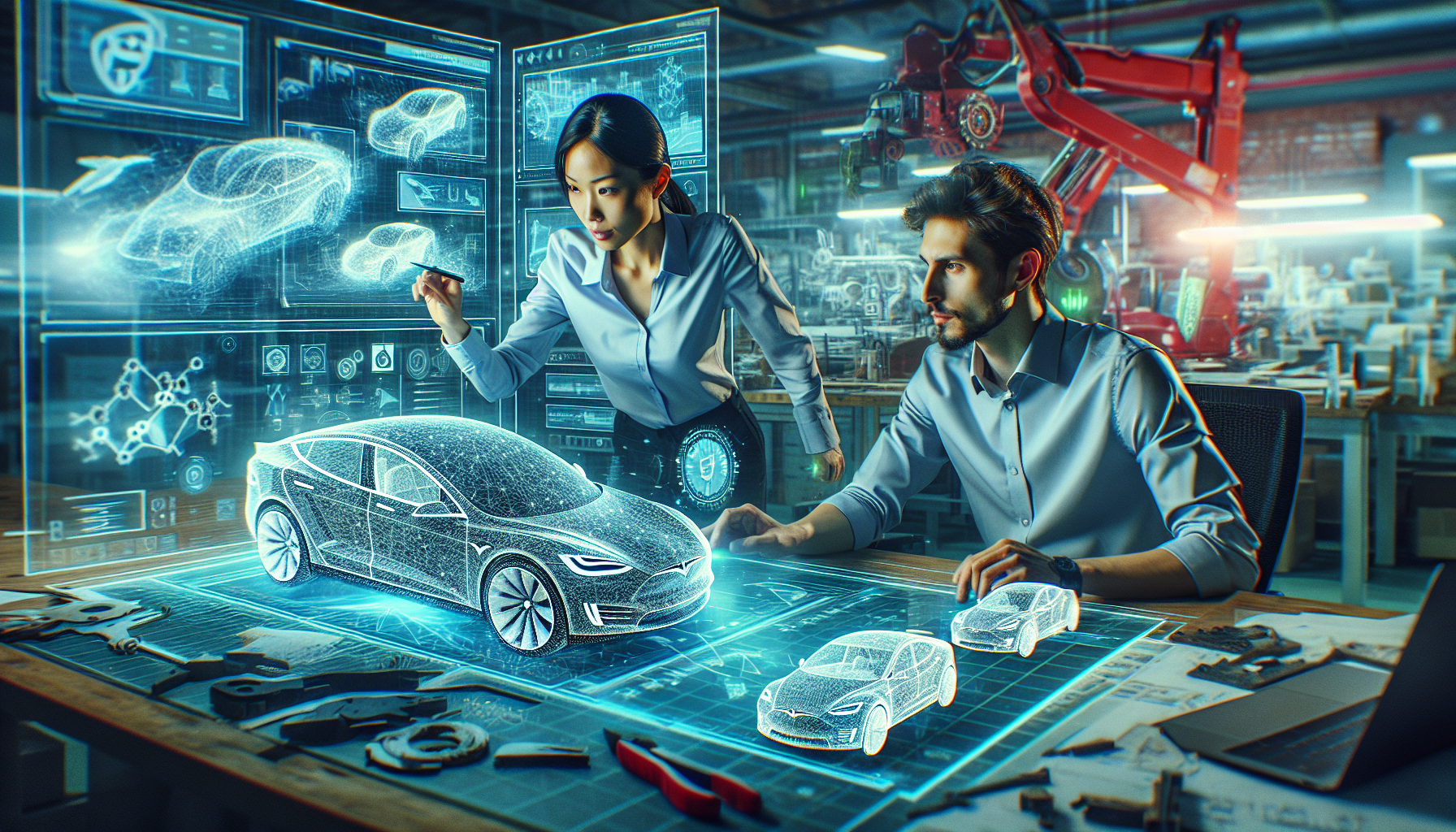

Utilizing Automation and Technology

Tesla Inc. is at the forefront of utilizing automation and technology to enhance its manufacturing processes. As a Process Engineer, you will play a crucial role in implementing robotics and automation to improve productivity. This includes utilizing data analytics for process optimization and integrating advanced technologies into the manufacturing processes. You will also be responsible for monitoring and managing computer-controlled systems to ensure smooth operations.

Maintaining Safety and Efficiency

Ensuring the safety and efficiency of the manufacturing processes is of utmost importance. As a Process Engineer, you will be responsible for ensuring compliance with safety regulations and protocols. This includes implementing safety measures to protect workers and equipment, conducting risk assessments, and implementing preventive measures. Optimizing processes for resource efficiency is also a key aspect of maintaining safety and efficiency.

Continuous Improvement

Continuous improvement is a core value at Tesla Inc. As a Process Engineer, you will be expected to consistently seek out new opportunities for improvement. This involves researching and evaluating new technologies and materials that can enhance the manufacturing processes. Collaboration with the research and development (R&D) teams on future product development is also essential in driving innovation and advancing the manufacturing capabilities of Tesla Inc. Implementing sustainable practices for environmental impact reduction is another important aspect of continuous improvement.

Future Innovation and Development

Future innovation and development are critical to the success of Tesla Inc. As a Process Engineer, you will actively participate in researching and evaluating new technologies and materials that have the potential to revolutionize the manufacturing industry. Collaborating with the R&D teams on future product development is essential, as this ensures that the manufacturing processes are aligned with the company’s vision. Implementing sustainable practices to reduce environmental impact and drive innovation and advance manufacturing capabilities are also important in shaping the future of Tesla Inc.